wavePREP

fast cleavage and deprotection

of oligonucleotides and peptides

» this machine did a great job «

biotechnology company from Germany

The Covid-19 pandemic has made mRNA vaccines world-famous and the technology behind them is booming. Our development of the wavePREP accelerates part of the work and supports the development process. But this time saving instrument can not only be used in biotechnology. All areas of DNA/RNA development and use benefit from wavePREP, which offers time savings of up to 90%.

With the precise combination of pressure, fast heat and your solvent (liquid and gaseous), you design your process to be exactly repeatable according to your requirements. A system for the small-, mid- and large-scale processes.

main advantages

fast facts listing

• Suitable for processing DNA-/ RNA-oligonucleotides and peptides

• Several process steps combined in one device

• Direct alkaline gas-phase cleavage from the support material

and removal of the protecting groups

• Direct further processing without evaporation of the liquids necessary

• Only 30 to 90 minutes for the entire process

instead of several hours (4 to 28 hours)

• Takes over the entire process aft er the solid-phase oligonucleotide or

peptide-synthesis and before HPLC purification/desalting in one pass

• A system that can be used for small-, mid- and large-scale processes

• Various work steps such as manual work with a pipette, shaker,

incubator, centrifuge, vacuum concentrator etc. are completely eliminated

• Because only one step is necessary, possible errors are eliminated, the

compound are more homogeneous and the quality of the results is better

• Direct processing of liquid chemicals in gaseous form,

so no expensive purchase of gaseous media

• Lowest operating costs due to highest speed, quick processing,

compactness, little staff and low use of chemicals

• High throughput solution system with microwave

pressure reactor and controlled gas phase reaction

• Easy handling of a large number at the same time

• Extremely high sample throughput due to fast heating and cooling

• No preparation by gas phase reaction necessary

• Optimal protection of laboratory staff through

minimal contact with chemicals

• Much less smells of ammonia etc. due to closed and automatic suction

• Significantly higher efficiency

• Automatic sample lift

• No comparable device on the worldwide market

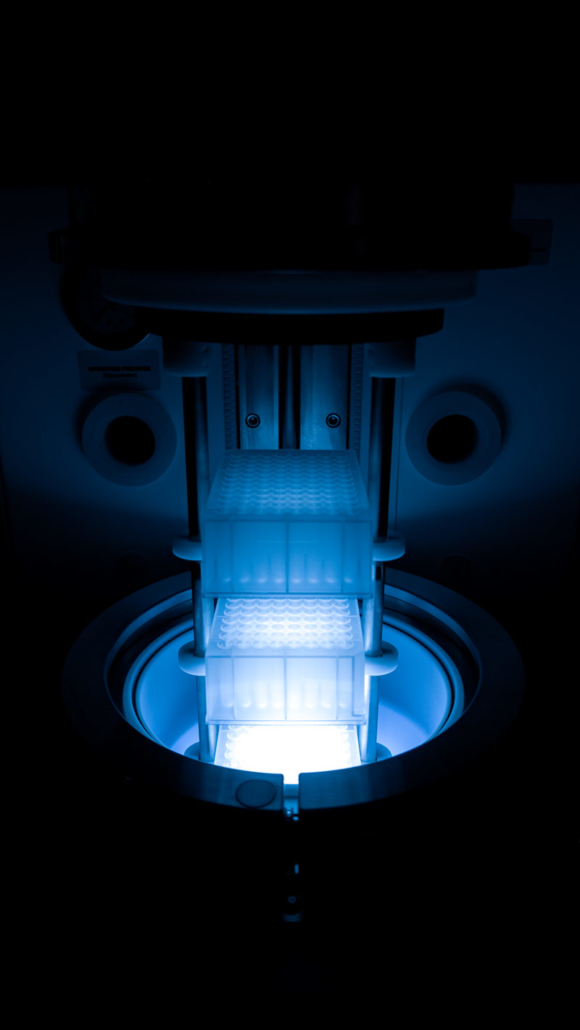

THE HIGH-SPEED MICROWAVE REACTOR

you save time, instruments, chemicals, space and manpower

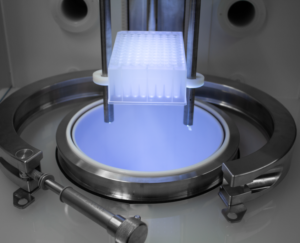

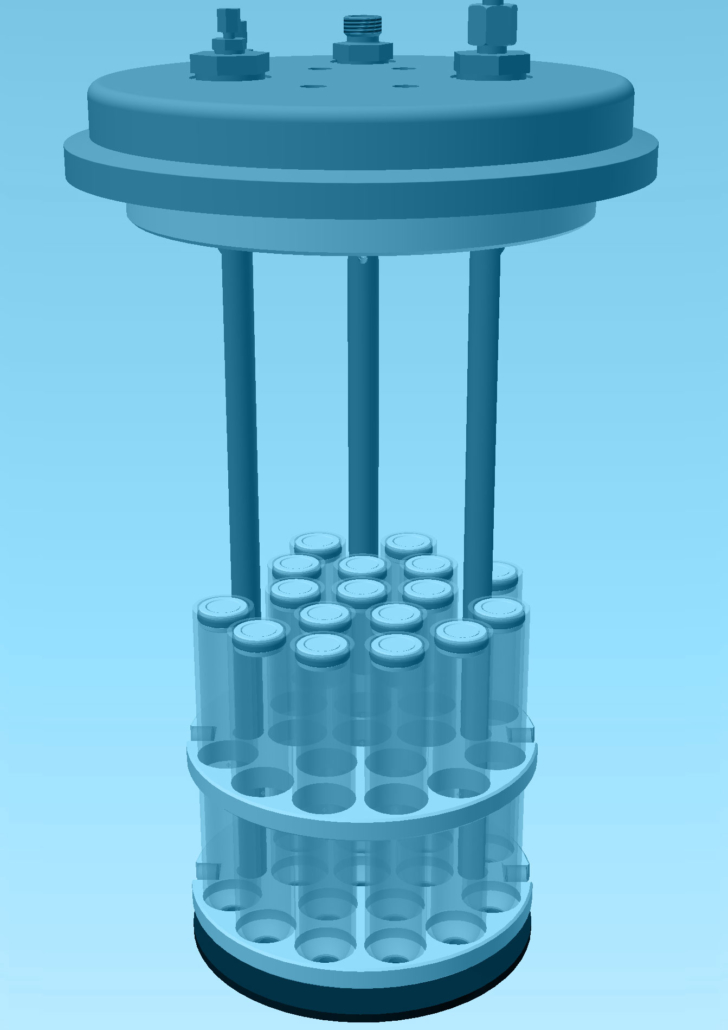

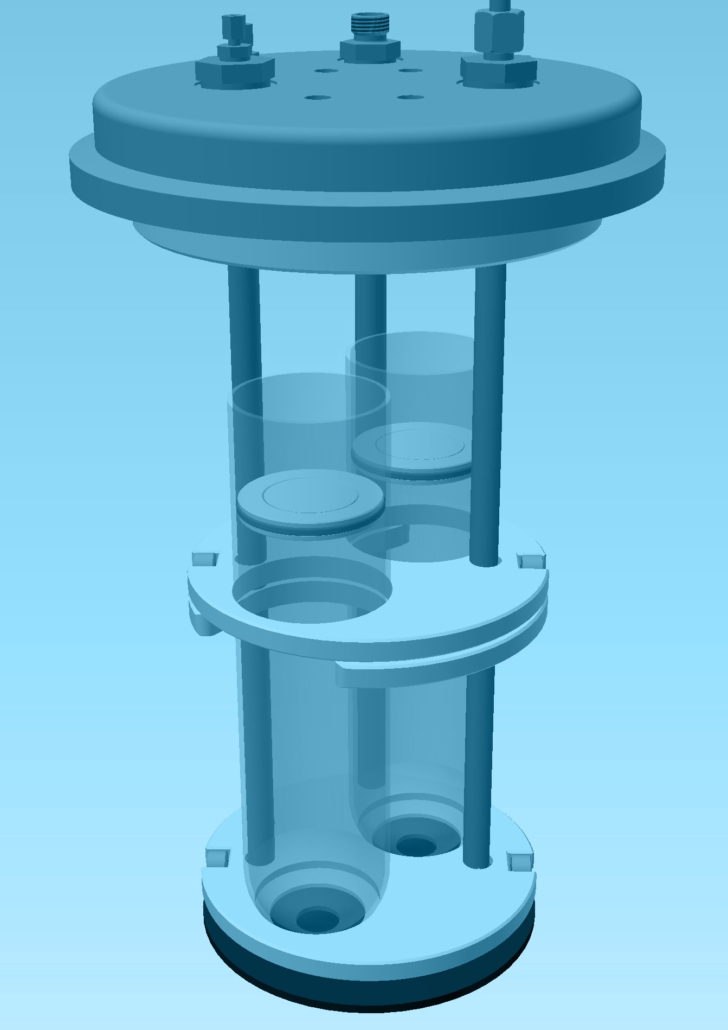

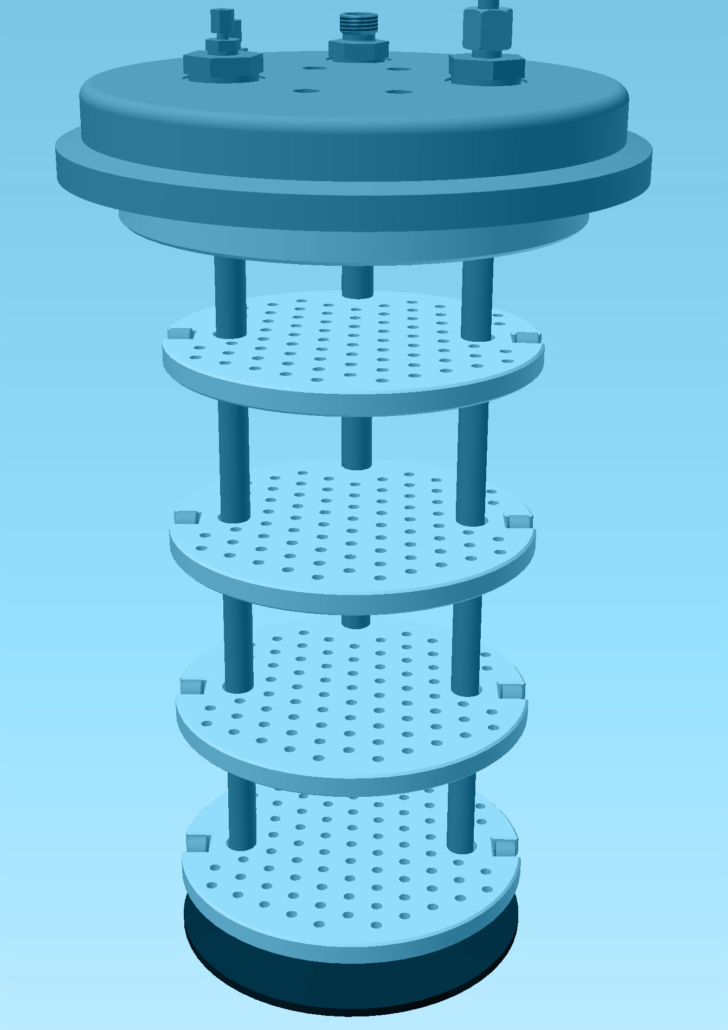

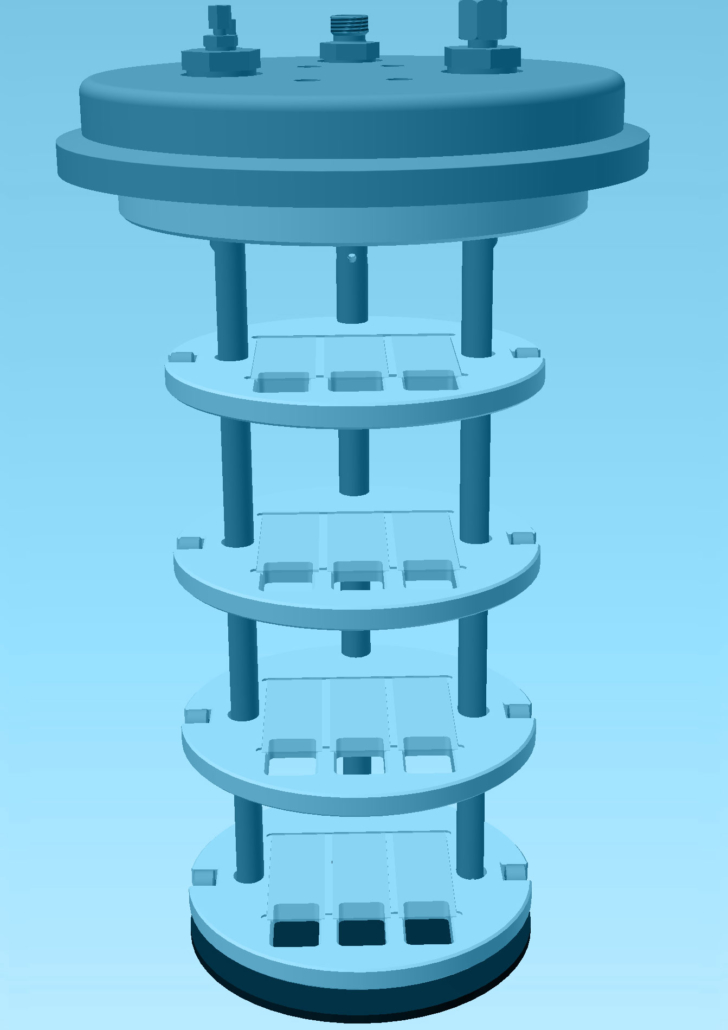

Our newly developed technology is worldwide unique in the production of oligonucleotides and peptides. The reaction can be carried out directly after the synthesis in sample holders with various inserts such as glass containers, deepwell plates, columns or microscope slides. Several sample holders can be used in the 10-liter pressure reactor, which considerably reduces the handling effort.

With just a few simple steps and clicks, the electrical lifting system is closed and the process started, all in less than 2 minutes. Aggressive reaction gases are extracted during the run and our unique opening and closing process protects the safety of laboratory personnel. The reaction of the compounds takes place in the gas phase under the influence of pressure and microwave. The high gas phase concentration leads to a complete and homogeneous reaction within a few minutes.

In the wavePREP system, all operating parameters are permanently checked and according to the program conditions regulated, graphically recorded and saved for quality controls. During the entire process the pressure and the temperature are controlled in the liquid reagent as well as in the gas phase. The results are fast, qualitative, homogeneous, cleaved and deprotected oligonucleotides and peptides, which can be used directly for purification, desalting, analysis, quantity and quality determination in the HPLC or LC-MS system if required.

MULTIPLE USAGE IN ONE SYSTEM

different uses for small-, mid- and large-scale processes

The wavePREP system has almost no limits. Whether oligonucleotides or peptides, whether glass containers in various sizes, deepwell plates, columns or microscope slide. With the right method and the use of the chemical, our microwave reactor processes all common products.

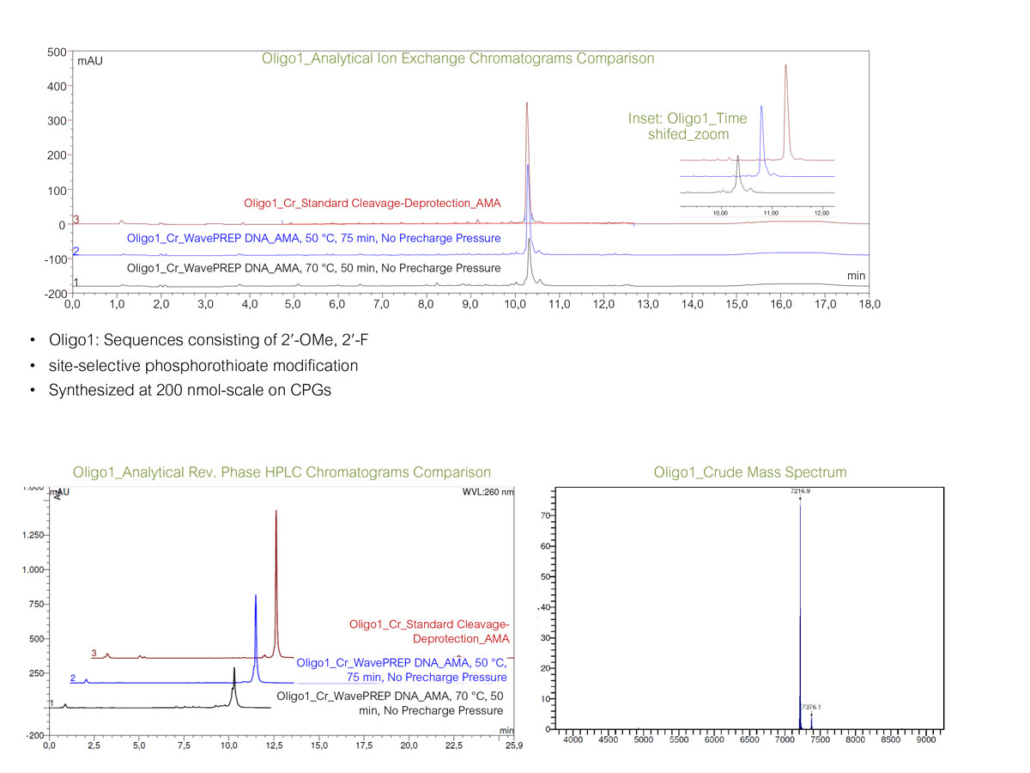

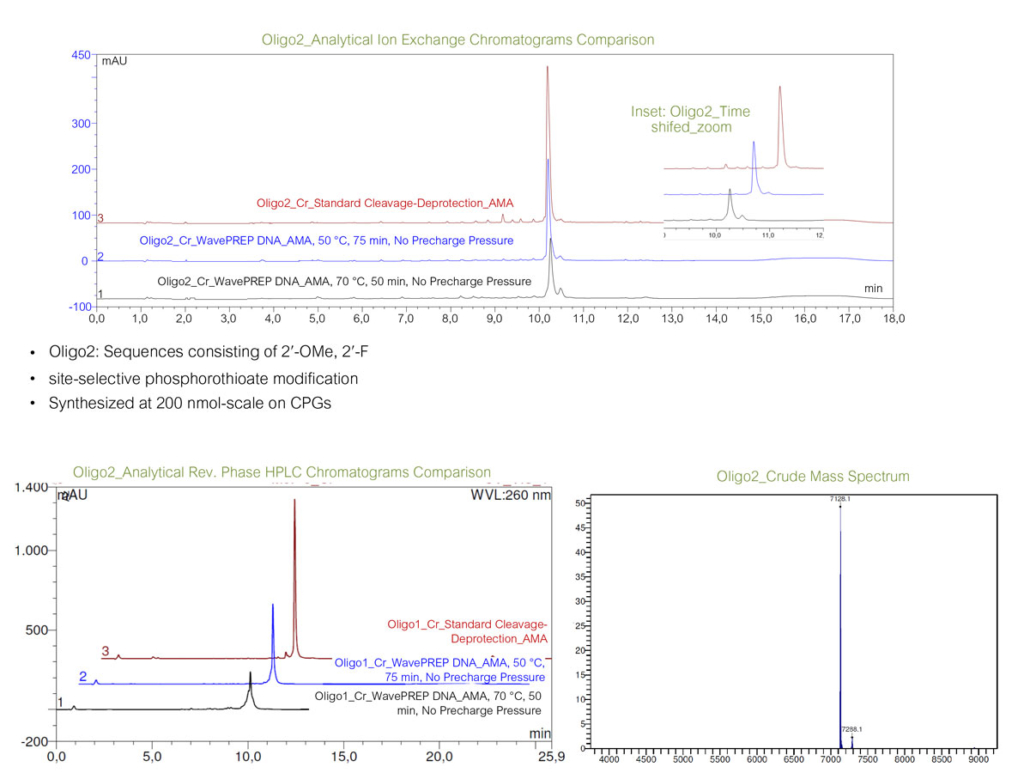

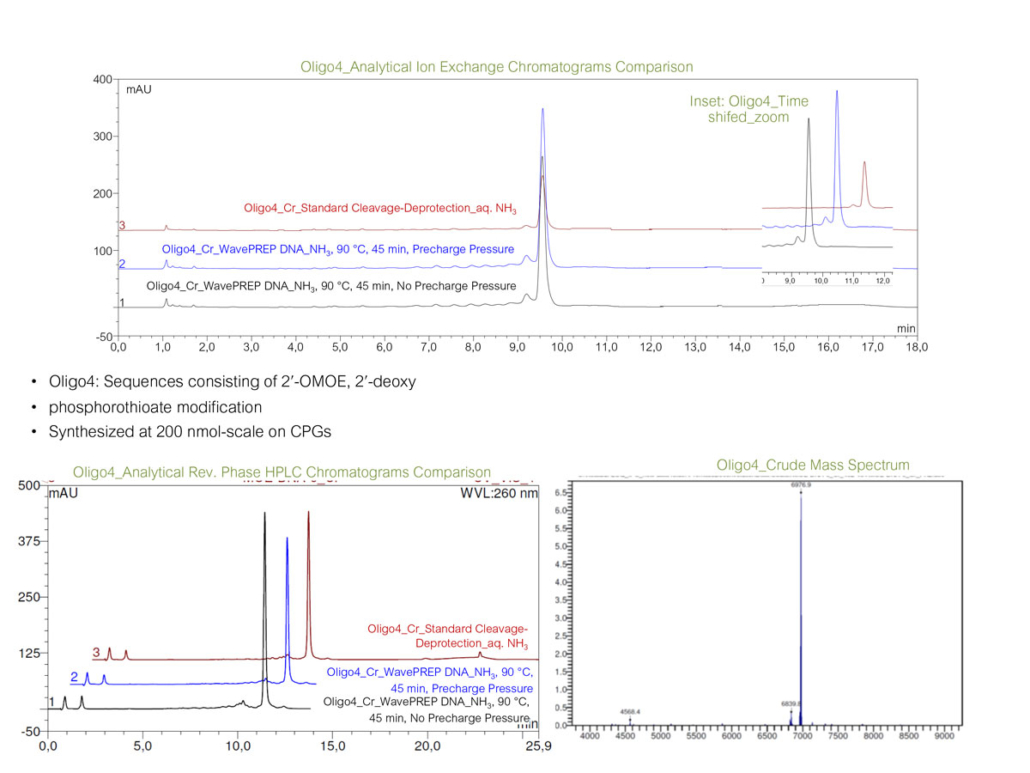

RESULTS THAT SWEEP YOU AWAY

comparison between the wavePREP and standard process

In some examples one of our customers shows results with a standard deprotection compared to two different versions with the wavePREP with different temperatures and times.

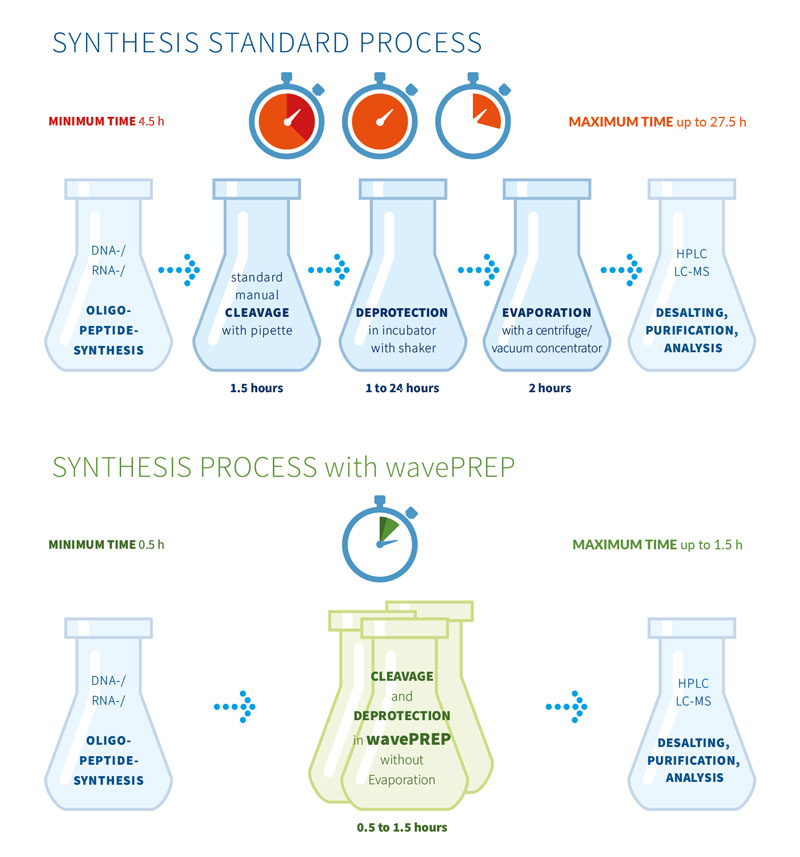

TIME COMPARISION between standard process and wavePREP

Up to 90% faster processing with fewer instruments and laboratory space

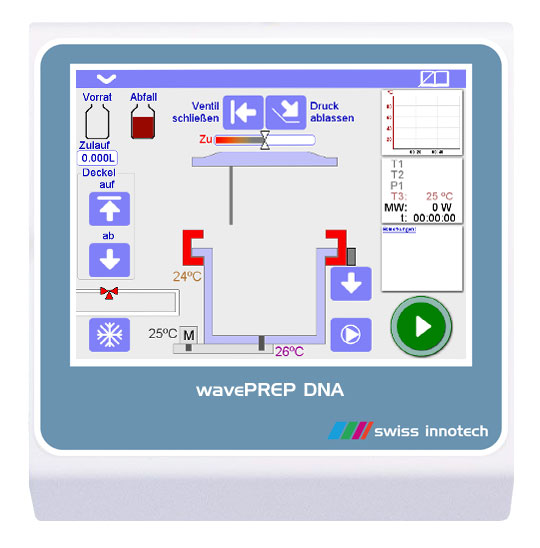

μCONTROL TERMINAL

the intelligent control and evaluation system

The wavePREP system is controlled via a user-friendly, compact terminal with an easy-to-read, bright, full-colour touch screen. The variably adjustable observation angle of the screen ensures optimum handling. Various connections for USB, mouse, keyboard, printer, network, analytic scales and video signals are also components of the terminal, such as the pre-installed easyCONTROL software.

The easyCONTROL is an operating and evaluation program developed inhouse and perfectly adapted to the requirements: userfriendly, multilingual and equipped with matching icons. In addition to the display of reactor temperature and pressure, the gas phase temperature, microwave

power, reflection, time and the magnetron are also calculated. In just a few steps you can create your own methods by entering time, power, temperature and pressure. These are displayed graphically and evaluated in a tabular form. Only one push of a button („Touch“) is required to launch a saved method and start the process. All protocols and results can be archived and printed out directly or via a PC as a report with diagrams.

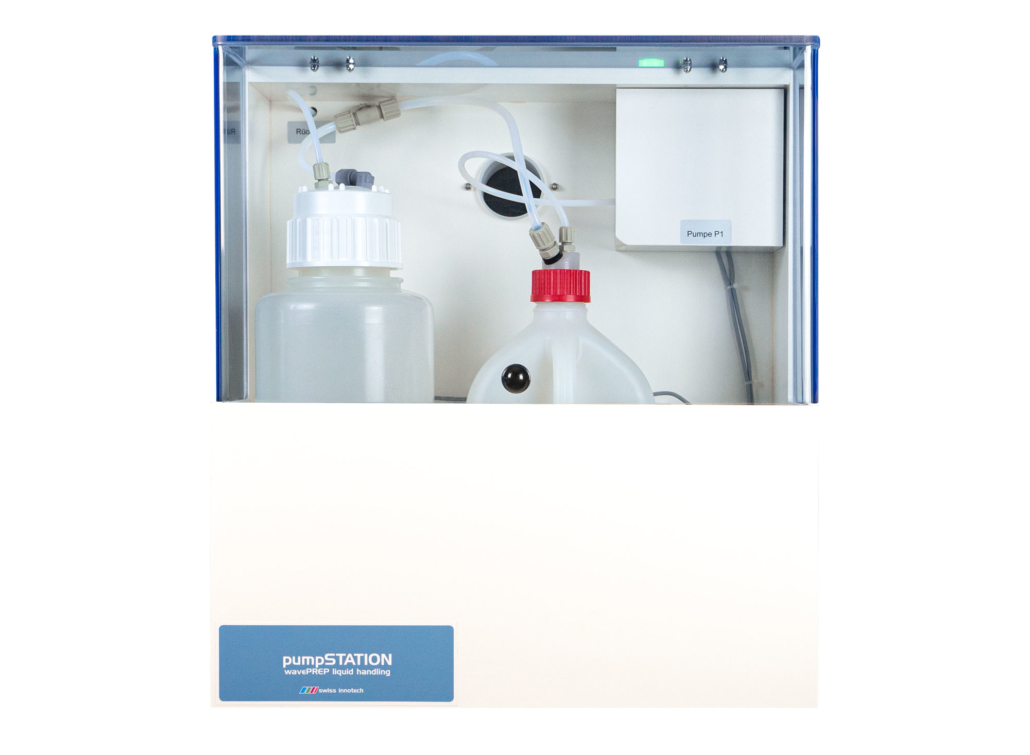

pumpSTATION

wavePREP liquid handling

With the pumpSTATION, the microwave reactor of the wavePREP system can be automatically filled and emptied. This minimizes the handling of chemicals and creates a safer environment for users. The filling level sensors recognize the liquid quantity which is in the containers and calculate at the same time whether a run can be started. If there is too little liquid in the tank or the waste container is full, the release for a further run is automatically blocked. In order to regain the approval for a new run, neither the waste container should be emptied nor a new chemical storage container should be used. The sensors then releases the operation again.

TEMPERATURE AND PRESSURE SENSORS

always the right settings – without compromise

A temperature sensor protected by a thermowell allows automatic display and monitoring of the internal temperature of the pressure vessel. In addition, a pressure sensor monitors the internal pressure, while a safety valve protects the pressure system from exceeding the permissible operating pressure.

email us for more information